London, UK (CNN) – Volkswagen has unveiled a massive expansion in battery production as it seeks to advance the electric race.

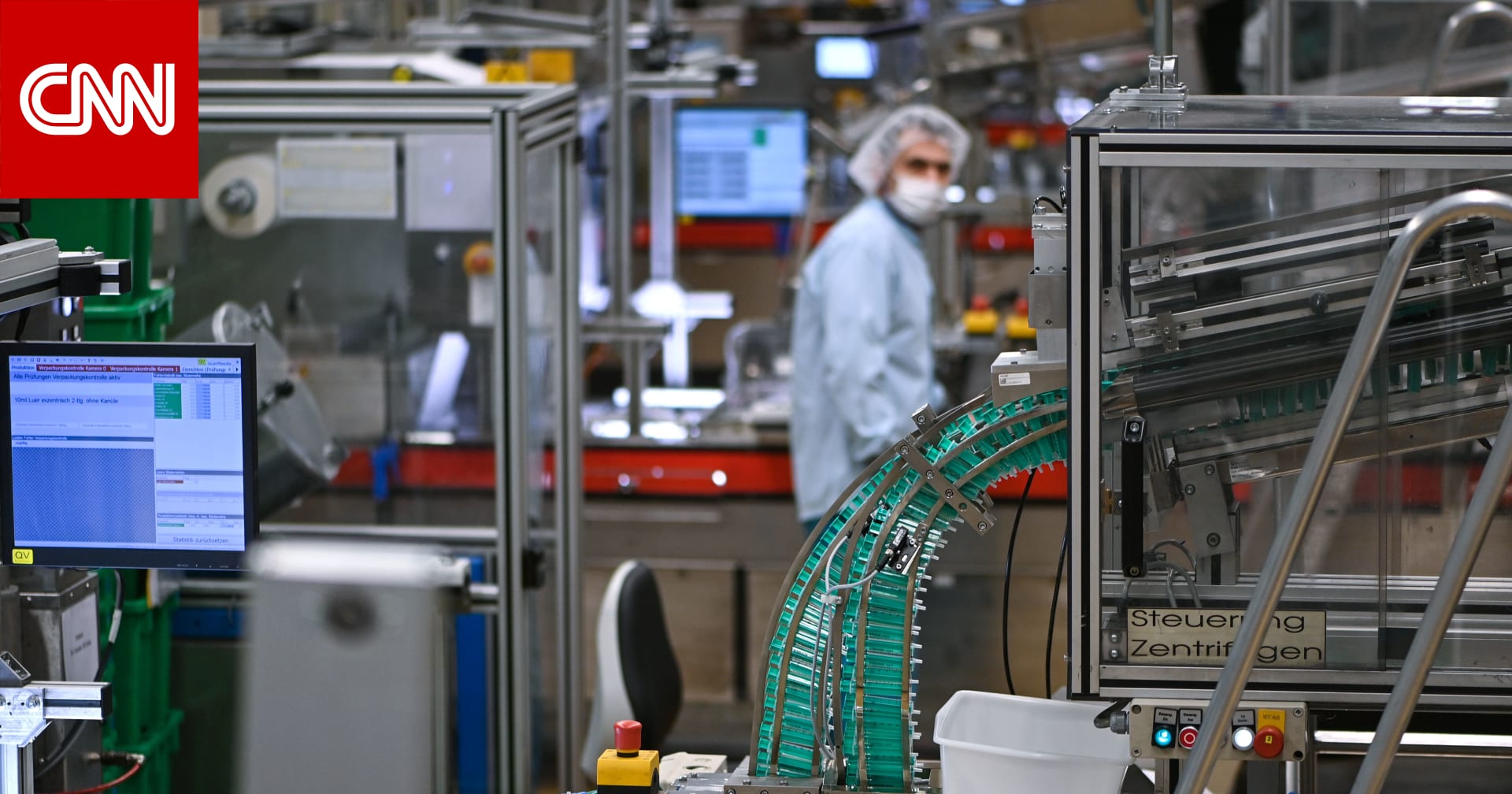

The German car manufacturer said on Monday that it plans to build 6 “mega factories” in Europe by 2030 with a total production capacity of 240 gigawatt hours per year, enough to power about 4 million “Volkswagen ID.3” electric cars, according to a spokesman. Official company name. The first battery manufacturers will operate in Skelleftea, Sweden, and Salzgitter, Germany.

Volkswagen will also add a large number of new electric vehicle charging points to networks across Europe, the United States and China, the company announced at an event on Monday.

Volkswagen’s EV strategy is to reduce the cost of battery systems through a new unified battery cell that will be launched in 2023 and installed in up to 80% of the company’s electric vehicles. The company also plans to recycle up to 95% of the raw materials used in battery production.

“One size that fits all cell designs will reduce battery costs by up to 50% compared to today. Lower battery prices mean more affordable cars, making electric cars more attractive to customers,” the company’s CEO, Herbert Des, said at an event on Monday. .

“Volkswagen said in a statement that battery costs, which make up a large proportion of the total cost of an electric vehicle, will gradually decrease by up to 50% in entry-level car models and by up to 30% in standard car models.”

The company also needs a safe source of battery cells as it increases production of electric cars.

Volkswagen started to gain from Tesla in its bid to become the world’s largest producer of battery-powered electric cars.

The company sold 231,600 battery-powered electric cars in 2020, less than half the number of Tesla sales, but an increase of 214% from the previous year.